Case Study: How Talen Tools solved labor shortage with Pickit

Recent studies show that 4.6 million manufacturing jobs will be created in the next decade in the US alone due to retirements and natural growth of the industry. However, many job-seekers aren’t interested in doing the repetitive and dull tasks they picture in manufacturing. Half of the vacancies are expected to stay unfilled due to lack of labourers skilled and willing to do these jobs.

The good news? There’s a solution!

Watch the video below or read on to find out how Talen Tools solved their labor shortage.

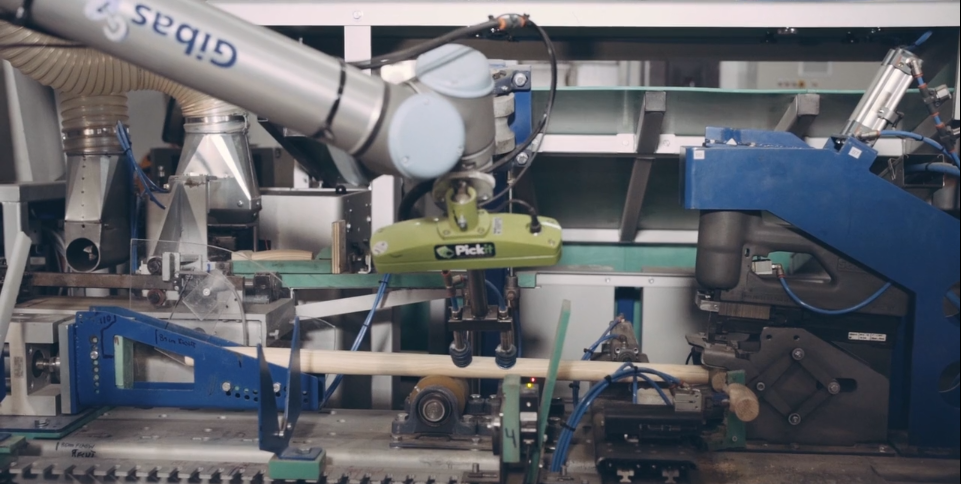

Enter cobots with eyes

Take a collaborative robot, add a Pickit 3D vision system, and automate your production process. Let automation take over the dull and monotonous tasks and let your employees do the tasks that give them variation and satisfaction. This is exactly what the Dutch company Talen Tools did - the result? They doubled their production with half the workforce and improved employee happiness.

Less vacancies, more employee happiness

We paid a visit to their gardening tools factory and spoke to the Managing Director Roelof Talen and trusted technical advisor Lubbert Talen. A shortage of laborers was their primary reason for looking into automation and vision solutions. They struggled to find workers willing and able to do certain tasks and felt obliged to find an alternative. Moreover, the general manager is very clear: he wants his employees to feel happy and satisfied in their role and realises this is not always the case when they’re only doing repetitive and boring tasks.

"We used to finish 400 broomsticks with 6 people. Now we finish 1000 broomsticks with 3 people."

High productivity and flexibility

By automating their production process, Talen Tools drastically increased their capacity and productivity. “We used to finish 400 broomsticks a day with 6 people in a high-pressure environment; after automating with Pickit, we now easily finish 1000 broomsticks with only 3 people that are experiencing less pressure and are generally happier in their place” said Managing Director Roelof Talen, who wants his employees to be content, but wants to see objective results as well.

Thanks to the flexibility of the Pickit product, Talen Tools can distinguish itself from its competition by being able to act quickly and change parts easily upon their clients’ requests. “This also makes it a good solution even for small batches,” according to the technical supervisor. Pickit uses 3D pictures instead of CAD models, which is also a plus for Talen Tools, since CAD models aren’t available for any of their parts.

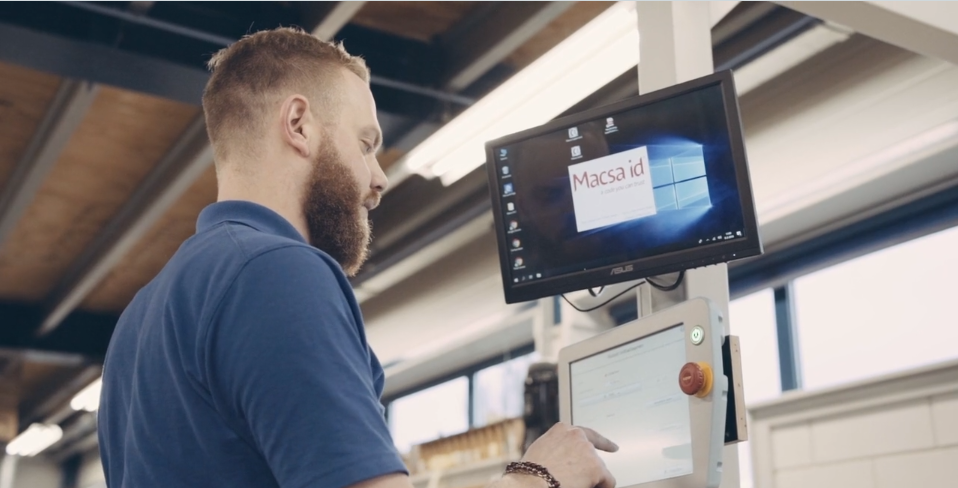

Ease of use

The last advantage according to Technical Advisor Lubbert Talen is the overall ease of use of the Pickit vision system. “You can build very nice applications without much in-depth knowledge about vision. One of the strong points is the user interface. What you see is what you get. You don’t need code to program the system - you do it in a very intuitive, visual way and don’t need a highly educated technical programmer.” Lastly, Lubbert Talen praised Pickit’s great support using snapshots, stating he always gets a reply to his questions in 1-2 days.

The benefits of automation using Pickit

Talen Tools is one of the hundreds of companies worldwide that’s been convinced by the advantages of automating your production processes using Pickit. It’s flexible, easy to use, reliable and a great way to fill in the many estimated manufacturing vacancies in the next decade.

Talen Tools doubled their production with half the workforce. Do you want to find out how Pickit can benefit your company too? Leave you email address below and we'll contact you!