Automation roadmap: when should you start with vision?

Are you considering automation, but you're not sure if you're ready for robots with eyes? Let's have a look at the automation possibilities and find out which is the right way to go for your projects.

1. Hard automation

The big advantage of hard automation is high throughput... Whereas the main disadvantage is a lack of flexibility.

Here's a few statements you might relate to:

If you're working with manual loading and fixtures

- Designing a fixture (trays/jigs) for my parts is costly

- I have different parts - and therefore, I need many custom fixtures

- Part presentation or machine loading take a lot of my operator's working time

If you're working with bowl feeders

- Our parts don't fit the bowl feeder.

- I have space limitations and bowl feeders are bulky.

- Time to market is crucial, and I can't wait for the delivery of custom-engineered solutions

Does any of this sound familiar? Then you should consider moving forward with vision.

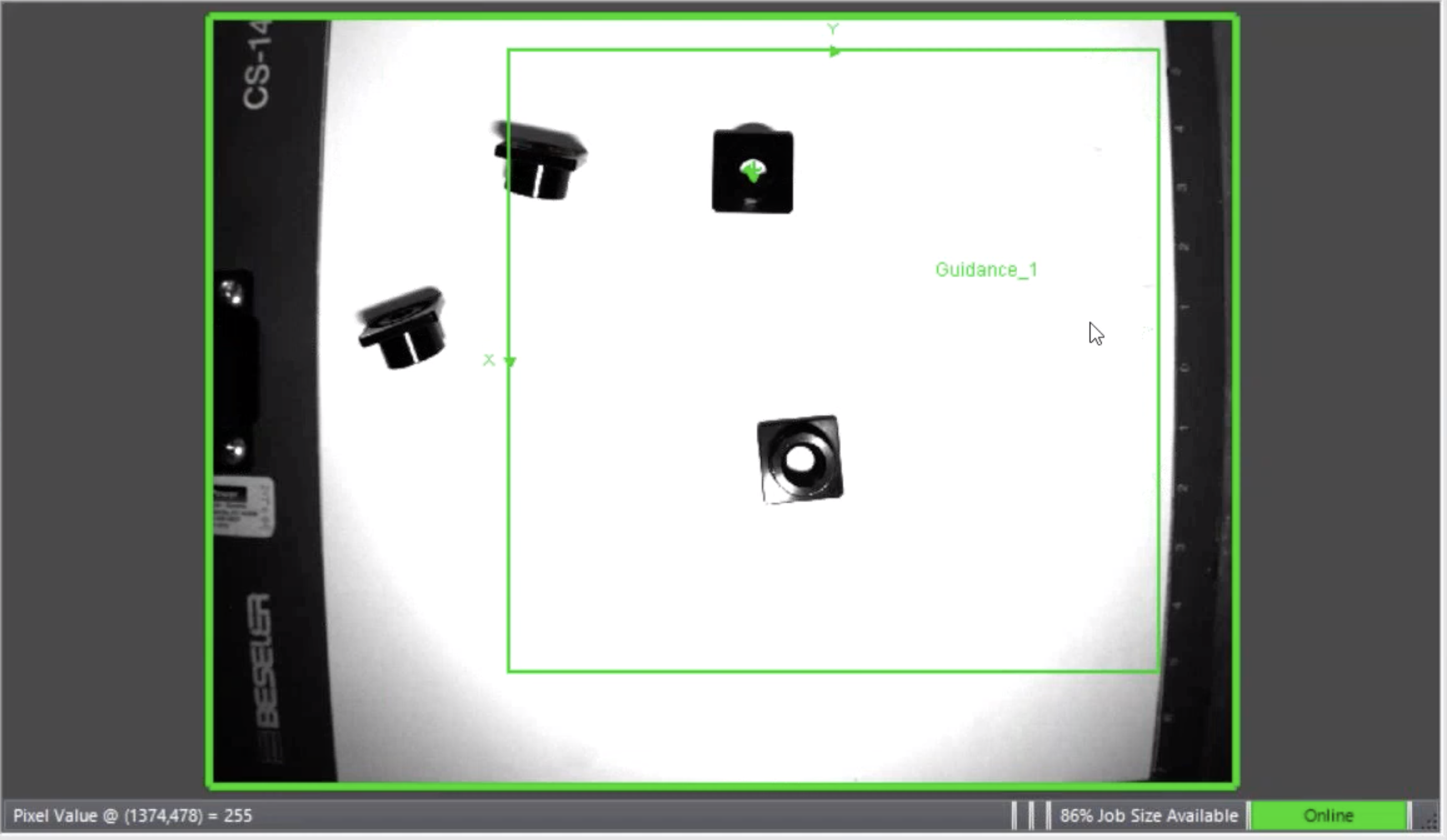

2. 2D vision

The big advantage of 2D vision is its cost-effectiveness.. Whereas the main disadvantage is a lack of flexibility and not having the ability to handle complex processes.

2D vision is a cost-effective solution if your parts are a) flat, b) non-touching and c) lying on a conveyor belt or table. However, 2D is not a good fit if a) your parts aren’t flat, b) there’s a lack of contrast between your parts and the table/conveyor belt, c) the influence of outside lighting creates shadows. These elements will confuse the camera.

Time to check out other options!

3. 3D vision

The big advantage of 3D vision is its flexibility:

- It solves applications with overlapping and glossy parts which vary in shape and size

- You can teach the system to detect and handle a whole variety of objects

- You can achieve fast changeovers: when you're done with a part, just remove the empty bin and place a new bin with the next product

- Modern 3D vision systems have a small footprint and are compatible with all major robot brands

On the other hand, 3D vision can have some inconveniences as well: slower cycle times and gripper limitations are a reality.

It's important to weigh out the pros and cons of all automation options when making your decision - email us if we can guide you through this process.

This post is an excerpt from our guide to bin picking in the automotive industry.

Keen to learn more? Leave your details and receive the full guide in your inbox.

-1.png)