Case Study: How to use 3D vision for dull, dirty and dangerous tasks.

Manufacturing is often characterised by 3D tasks: they’re dull, dirty and dangerous. Many workers in manufacturing still spend their days performing repetitive actions in a noisy, messy and hazardous environment. This can affect employee welfare and it can even create labor shortage in the long run. However, today, a lot of 3D tasks can be taken over by robots, relieving the workers from their risky duties. As a result, these human workers are free to focus on tasks that are more complex, more diverse, and generally safer.

Watch the video below or read on to find out how the animal feed production company Van Tuijl used Pickit to increase production and employee welfare.

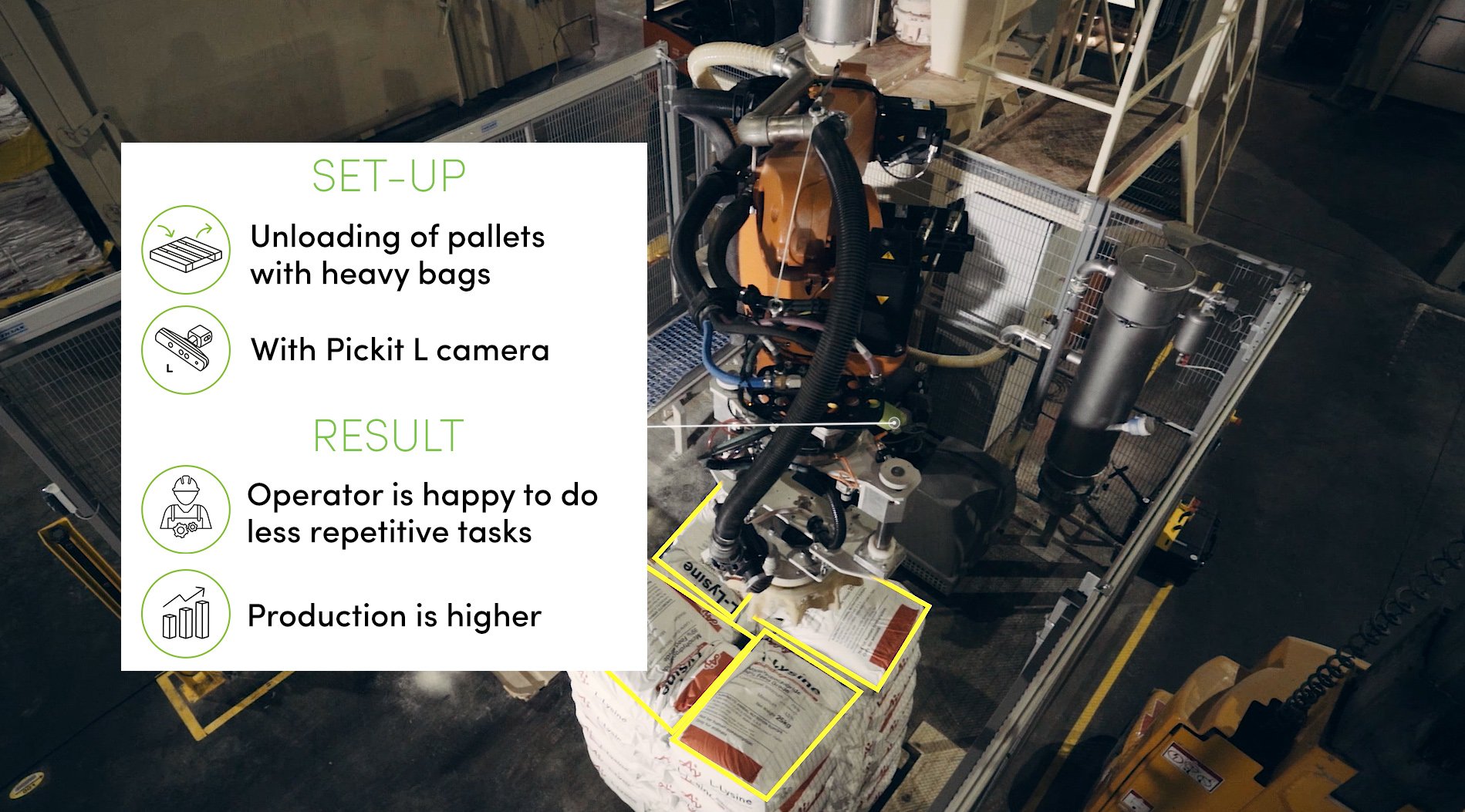

As the core business of the Dutch company Van Tuijl is animal feed production, it’s not surprising that thousands of heavy bags need to be handled every day. Before automating with Pickit, the unloading of pallets with bags of different weights and sizes was done manually, in a less than ergonomic way. This could lead to back problems and general unhappiness among employees.

Van Tuijl understood this, and chose to automate their depalletising process using a KUKA robot and a Pickit 3D vision system. Their weapon of choice was the Pickit L, as it can easily detect randomly stacked bags on pallets. The application now runs with minimal supervision and the operator sees even more advantages:

“While we are getting pallets or while we’re on a break, the application can keep running without any interruptions, which increases production.”

Are you looking for an automatic solution for unloading pallets? Leave your email below to be contacted by our team.